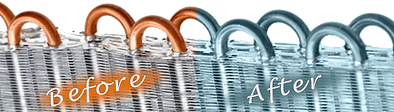

Solution: Cooling Coil Rejuvenation

Solution: Cooling Coil Rejuvenation

Cooling Coil Rejuvenation - coatings are the first field

applied corrosion protection coatings that actually

“Rejuvenates and Restores” marginally deteriorated

aluminum coils and copper tubes with its unique

aluminum impregnated polyurethane coating.

- HVAC/R Rejuvenation Coating that can be field applied in temperatures from 20⁰ to 140⁰ F

- Contains 65% aluminum paste that binds and restores failing and deteriorating coils and metal surfaces

- Is an ultra thin (1 ml) spray application coating that allows for maximum heat transfer and extraordinary life extension

- Contains zinc phosphate: a rust inhibitor

- Tests by 3rd parties usually demonstrate 10-20% energy savings on rejuvenated equipment

“Premature functional obsolescence of HVAC/R equipment is an unfortunate reality of today’s facility managers, engineers and building owners.”

This is due to a number of factors including but not limited to: cost saving initial designs, harsh environmental operating conditions and reduced maintenance and capital replacement budgets. These realities combined with the increased pressure to run our facilities more efficiently have been the catalyst for the development of HVAC Armor DX.

Applied exclusively by experienced HVAC Armor Certified Professional Applicators. HVAC Armor DX is an affordable green initiative that increases HVAC energy efficiency and cost savings.

Applied exclusively by experienced HVAC Armor Certified Professional Applicators. HVAC Armor DX is an affordable green initiative that increases HVAC energy efficiency and cost savings.